What is Mokume-Gane?

At CarbonShavingCo, we pride ourselves on using exotic materials in our custom Cx safety razors, and one of our most unique offerings is the mokume gane razor. If you're seeking a high-quality, unique safety razor that provides an exceptional shave, mokume gane might just be the material you're looking for. Pronounced "Moe-koo-may Gah-nay," this centuries-old technique is steeped in history and artistry.

The History of Mokume-Gane

Originating in 17th-century Japan, mokume gane was first used to decorate samurai katana swords. Sword-making was revered as the highest form of artwork in Japan, and this skill was meticulously passed down through generations. Denbei Shoami, a master metalworker, perfected this process between 1650 and 1728, forging some of Japan's finest swords.

However, as the need for swords declined, this intricate skill almost faded into obscurity. It wasn't until Tiffany & Co. designers resurrected the art in the 19th century, using silver to create award-winning pieces, that mokume gane regained prominence. In the 1970s, Hiroko Pijanowski reintroduced the technique to the United States after learning from a Japanese master craftsman.

Forging Mokume Gane for Custom Safety Razors

The process of creating mokume gane involves fusing different non-ferrous metals under high pressure and heat. This technique, requiring meticulous cleanliness to avoid impurities, results in a metal that is not just a surface treatment but has forged layers running through the entire razor. The term "Mokume Gane" translates to "Wood Grain Metal," referring to the wood-like patterns it creates.

Crafting a Mokume Gane Safety Razor

The metal in our mokume gane razors are custom forged in the United States by master blacksmiths skilled in this specialized art. We are currently the only company making mokume safety razors, and each piece is crafted to order.

The forging process involves laminating layers of metals such as copper and brass, which are then twisted and compressed to form unique patterns. Achieving the perfect fusion requires precise temperature control; too much heat and the metals melt, too little and they won't bond.

Machining and Finishing Mokume Gane

Once forged, the mokume gane must be carefully machined. Orientation of the pattern is crucial to maximize both strength and appearance. Machining mokume gane is similar to brass but requires slower processes due to the inclusion of softer metals like copper.

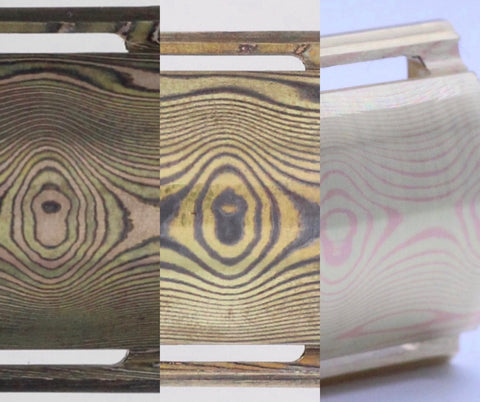

After machining, each piece is hand-sanded to remove machine marks and achieve a smooth finish. Various patinas can be applied, from natural aging to forced methods using traditional Japanese techniques or modern chemicals.

The Beauty of Mokume Gane Patinas

The patina process, which can be natural or forced, adds unique colors and patterns to the mokume gane. Traditional Japanese methods like Niiro and Rokusho create distinct effects, while modern approaches using ammonia or even eggs can produce unique hues.

Shaving with a Mokume Gane Safety Razor

Mokume gane razors are heavier than stainless steel and offer a unique feel. The material's natural patina evolves over time, giving each razor a distinct appearance. Proper care, including regular cleaning and occasional repolishing(or not!), will ensure your razor remains a beautiful and functional piece of art.

Join the Wet Shaving Community

Wet shaving is an art form, personal to your skin type and preferences. At Carbon Shaving Co, we design our razors to be functional pieces of art and easy to clean, perfect for sensitive skin. Join the wet shaving community to discover the best practices for a luxurious shaving experience.

For those interested in owning a custom mokume gane safety razor, Contact us

* Same razor but different patina(heat patina on the right)