Gallery

Our gallery includes custom safety razors, limited edition razors, small production runs and images we thought you might enjoy. Contact us if one of these custom Cx safety razor catches your eye...we update this page when we introduce a new material or piece. Each of our safety razors has either a unique serial number or a unique name...

If you want to learn more about our designs we talk in great detail in our blogs about design, material, techniques and the history of shaving.

Cx-Damascus safety razor

This custom all stainless Damascus steel is made up of both 304 and 316 stainless, folded and forged right here in the USA. The Cx-Damascus is not mass produced. This piece is a testament to that mission. These are the worlds first stainless steel Damascus safety razors.

One Black, One Blue

In our pursuit of one-of-a-kind pieces, we explore colors—each cap is forged from stainless Damascus steel, then coated and hand-sanded to reveal the folded patterns beneath - layer by layer, line by line. By sanding back the surface, we expose the pattern: colored valleys in 304 stainless, and polished peaks in 316L. A layered dialogue of color, contrast, and craft.

One wears blue: a proprietary CarboBlue™ titanium-based PVD finish. Shifting with the light - cool, electric, unpredictable. A surface alive with motion. The Cx-Blue

The other, black: finished in traditional Diamond-Like Carbon (DLC). Unyielding. Understated. A mirror of discipline and depth. The Cx-Black

Cx-Mokume safety razor

Our mokume was expertly forged to create custom billets by master blacksmiths in the USA. We then carefully machined each piece to create the Cx-Mokume. We don't coat the metal with any wax. These pieces were "patina'd" using heat only, we stopped the process just as the colors developed on the mokume. The patina will naturally evolve with time and generations...

Cx-Copper safety razor

We make these pieces in very small quantities, are available on a limited basis and we change the design frequently. Copper is one of the earliest metals used for shaving, first used for shaving around 3000 BC as a sharpened blade, although native American's were known to have used copper as far back as 10000 BC. It is one of the few metals which occur naturally in it's solid metal state in nature. Copper is a good conductor of heat, soft and is recognized for its antibacterial properties. This metal will patina with time...the Cx-Copper.

Limited Editions:

Cx-Iliad (Available - Limited to 10 pieces)

The Iliad is the epic Greek poem that documents the siege of Troy...it also tells the story of the Titans. The Cx-Iliad is all Titanium and features a Damtanium cap, a forged material consisting of 2 grades of Titanium (Grade 2 and 5). This material is custom forged for us in the USA.

Cx-Carbide (Available - Limited to 10 pieces)

A Carbide is a compound made up of Carbon and steel or other metal. This combining of Carbon to steel has been a part of metal forging for centuries, it is believed the presence of carbon is what made the Damascus swords of the past notorious for their strength and sharpness. The Cx-Carbide is a mix of stainless steel damascus and 316L stainless steel.

Cx-Lowe (Available - Limited to 6 pieces)

The brass handle and base plate were part of a limited run I created in brass. Each base plate is marked with the name of a naval ship. We paired a few of these pieces with a copper and brass Mokume cap. This piece was named the Cx-Lowe.

Light Weight Titanium safety razor

Cx-Atlas

The Cx-Atlas(left) is made from some of the lightest and strongest material known to man. This aerospace inspired Cx razor, continues to be made with USA forged titanium and USA carbon fiber. This is the lightest Cx we have made to date at ~30 grams. This razor is about 50% lighter than the 1945 Gillette Tech razor. The Cx-Ti/Web(right) is the all titanium version...48 grams is the total weight.

Both these models include our "Web Plate". "Lightening holes" commonly used in F1 race cars, aerospace, military and maritime designs, optimize weight and strength in designs. The open matrix structure allows for the free flow of debris, soap, air and water. We don't know of any lighter titanium razors on the market. Email us if you know a lighter one!

Cx-Damtanium (Titanium Damascus safety razor)

Damtanium is a forged material consisting of 2 grades of Titanium (Grade 2 and 5). This material is custom forged for us in the USA. The Cx-Damtanium razor is extremely light in weight similar to our Cx-Ti. Titanium was named after the Titans of Greek mythology...we named each of these Cx razor individually after these Titans.

Cx-Damascus/DLC

The photo belo is a picture of the Cx-Allos. Allos is the Greek word for "other"...it is also the root word for allotropy, which is the ability for an element to exist in 2 forms. Such is the way with the element Carbon...

DLC stands for "Diamond-like Carbon", this umbrella of coatings share similar properties to diamonds including their hardness, slickness and durability. We chose a Chromium based "DLC" coating for our 304/316 stainless steel Damascus because of its jet black color. We applied the coating on the stainless Damascus and then hand sanded the piece to reveal the striking contrast of polished stainless with the midnight black carbon coating, thereby revealing the forge pattern of the material...I custom make these pieces. Add your email here if interested in one or want to see more photos.

Cx-904L safety razor

904L steel was first introduced and used in the high-end watch market by the Swiss luxury watch manufacturer Rolex in the mid-1980s. Rolex began incorporating 904L into their watches as a way to enhance the corrosion resistance, overall durability, and appearance of their timepieces. Prior to this, they were using 316L stainless steel. We are the only manufacturer of safety razors to use 904L stainless steel.

Exotic Shaving Brush

We only make our products in small batches, this is our 2nd version of our shaving brush made from USA forged exotic material like stainless Damascus, Mokume and Titanium Damascus. Each brush is machined, assembled and hand finished in Minneapolis, USA...our knots are custom made and hand tied for us in Germany by local artisans.

Every brush handle is laser engraved with our makers mark, material and a unique serial number with the year denoted. You can see more of these custom handles here.

Cx-Graphite safety razor

The Cx-Graphite safety razor was machined from Titanium coated with a Diamond-like Carbon(DLC) coating. This DLC coating was graphite (Carbon) based. TaC is the hardest, strongest and slickest of the DLC platings and is considered the purest of the "Diamond-like Carbon" coatings. TaC DLC is slicker than mirror polished Titanium or 316L stainless steel...approaching that of Teflon, yet significantly more durable.

Cx-Titan

This was the lightest DE razor on the market until we introduced the Cx-Atlas. The Cx-Titan was 32-34 grams with a Perlage patterned cap and a Titanium/Carbon Fiber handle. It was also available with a 2-Tone base plate.

Cx-Crown

The British Navy were the first to use graphite as a mold for their canon balls, because of its strategic military value it was strictly controlled by the Crown. The cap of this piece is forged in the USA from 2 grades of stainless steel, machined and acid etched to reveal the unique pattern. The web plate is machined from titanium, the handle is titanium and carbon fiber….all USA sourced material! We polish the surfaces to a high polish and apply a Diamond-like Carbon coating. We only made 6 of these.

Cx-Sparta

A combination of innovative materials makes this piece both beautiful and light. Titanium, carbon fiber and custom forged stainless steel Damascus(Grades 304/316), all USA sourced material and USA made. This piece weighed only 47.5 grams.

Cx-Osiris

The Cx-Osiris is a one of a kind piece, this piece is part of our Damascus line, this run was named after gods or deities of conflict. This piece is all Damascus stainless steel(grade 304 and 316). Our inspiration for this piece comes from the lost art of Damascus steel used to forge swords of the past, they were renowned for their toughness and craftsmanship. Technically the term for this metal is "pattern-weld" as the true secret to the original "Damascus steel" was lost to time in the 1800's. Each base plate, handle and top cap was individually etched, hand sanded and gently polished. The Damascus steel was custom forged in the USA.

Cx-Brass safety razor

We made a small run of brass as a tribute to the early sailors, each of the Cx-Brass safety razors was named after a naval ship.

Covering the hulls of navy ships with brass was done to protect the the hull and give an edge in battle by allowing a ship to sail faster. Initially it was copper sheathing that was used but by 1850 it was a British inventor, George Muntz who pioneered a special brass alloy for sheathing.

Cx-Marine

Damascus Stainless steel head, titanium and carbon fiber handle. This Cx weighs 50grams. We named this “Marine” because the pattern of this damascus piece reminded me of the ocean. Earlier in my life I worked on boats in San Diego and everything about this Cx reminded me of a high performance, fine crafted boat. USA sourced carbon fiber, titanium knurled grips.

Custom Safety Razor

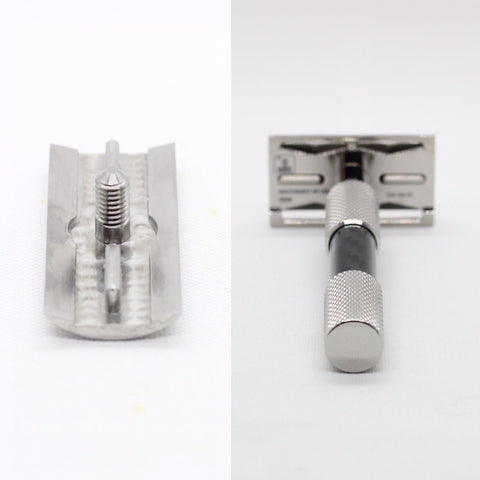

This was a custom safety razor we made for a customer. This Cx features a DLC (Diamond Like Carbon) Graphite coated cap, this is the purest form of DLC and is referred to as a TaC DLC coating. A TaC DLC coating is one of the hardest carbon coating you can apply and possesses some of the same qualities of diamonds including a very slick and hard surface, often used in the watch industry to prevent scratches. We included 2 base plates with this kit, the Original level/.68mm plate and a ++/1.08mm plate. We applied a 2-tone finish to the original plate. The handle and base plates on this DE safety razor are raw polished titanium and carbon fiber.

2-Tone Finish

A striking contrast shows between the high polish and bead blasted surface. These were a limited run we did in 316L and Titanium.

18K Red Gold inlay

Graphite inlay

18K Yellow Gold inlay

18K Red Gold inlay with G VS Diamond