What is Mokume-Gane

We use a lot of exotic material in our custom Cx line of safety razors and Mokume Gane is one of them. If you are looking for a high-quality yet unique Safety razor and love to enjoy a close shave, I thought I would write a blog specific to the material called Mokume Gane. It is pronounced, "Moe-koo-may Gah-nay".

Originally this material was first used in the 17th century in Japan, it was originally used to decorate the Katana swords of the Samurais. Sword-making was considered the highest form of artwork in Japan, this skill and technique were passed down through generations.

Denbei Shoami was the first to perfect this process sometime between 1650 and 1728, Denbei was a master metalworker who forged some of Japan's finest swords...over time the need for swords waned and the skill was almost lost to time.

It was actually the designers at Tiffany and Co. who resurrected the art, consequently winning great praise...they used silver in their Mokume and won numerous awards in a Paris exposition in 1877. It was still very rare to see Mokume techniques used through the middle of the 20th century.

It wasn’t until 1970 that Hiroko Pijanowski brought the material and techniques back to the United States after learning the difficult techniques from a Japanese master craftsman. For the most part, it was mostly known through remaining art and scholarly articles…

The tradition of this metalwork, its history, and its impact on generations inspired us to use this material in the making of some of our select Mokume Cx safety razors.

Forging Mokume Gane for a Custom Safety Razor

The forging of this material involves high pressure and heat to fuse different non-ferrous metals(non-iron-based metals) together. The process needs to be extremely clean to avoid forging impurities into the material. Paper layers of this material are layered on top of themselves and fused together. This metal is not a surface treatment but forged layers running through the pieces.

Mokume Gane roughly translates to “Wood Grain Metal” in English because of the patterns it creates in the metal. Generally, it is made with softer metals such as copper and brass but can also include silver and gold, and other precious metals. What makes this material so difficult to forge is that the temperature needs to be tightly controlled...heat it too much and it will melt. Don’t heat it enough and it will become brittle and the metals won’t fuse together. Modern techniques and furnaces are used to make the material today with the improved technology in presses and temperature-controlled forges.

Still forging this material requires a special skill that few blacksmiths and craftsmen have. It is different from forging Damascus steel and requires a much more controlled forge. Torque plates, hydraulic presses, hand forging, and hand twisting are used to create distinctive patterns. The key is laminating the different materials together carefully so, as to not completely melt the metals together or create voids in the material. If the material is forged with not enough heat or pressure, the layers will not fully bond and can delaminate when machining. Fire the metal too much, and the 2 different metals will melt together to form a new indistinguishable metal alloy. The billets and bars are then twisted and compressed to form unique patterns.

Mokume Gane Luxury Custom Safety Razor

We use only USA material that was forged in the United States by master blacksmiths skilled at this highly specialized form of art. Most of this material is used in fine jewelry. The result is a unique pattern that is void of inclusions and gaps.

Machining Mokume Gane:

Now that the material is forged, machining the material becomes the next challenge. First, we need to consider the orientation of the pattern to maximize its strength and appearance. It machines similar to brass however with the inclusion of copper, which is softer to machine, it requires a slow machining process. Coolant is used primarily to reduce the chip collection at the tools biting edge. Being so soft, it doesn’t heat up as much as our 316L stainless steel or titanium safety razors however achieving a smooth surface is critical to reducing machine marks.

Finishing Mokume Gane:

After machining, we hand sand each piece to remove machine marks from non-critical surfaces and dimensions. We also do final shaping at this point. We start with a very high-grit sandpaper and continue to step up the sanding grit to finer and finer sandpaper. For the final finish, we need to consider the type of patina we could apply, if any.

Natural Patina on a Mokume Gane:

What makes this material unique, is the patina that forms over the material with time. The patina forms a coating based on the shaving environment. This patina will happen naturally but it too can be controlled with many options and surface effects created.

Adding a Forced Patina to Mokume Gane:

In the early part of the 17th century, the Japanese used multiple ways to create the patina including Niiro or a “cooked color” which was created by boiling the metal in a special solution creating a heat patina effect. Different metals react differently to the patina process creating multiple colors on the Mokume. In Japan, this class of metalwork is called Irogane or “colored metal”. Rokusho is another traditional process used in the Niiro process. Below are a few more traditional Japanese patinas:

• Su-tanpan

• Niage

• Wara-ibushi

• The above are just a few...most are still kept secret by traditional craftsmen.

We have experimented with a lot of these patinas and also others including:

• Liver of sulfur

• Ammonia (This will actually etch the surface)

• Eggs – Yes eggs in a bag with Mokume will develop their own unique colors

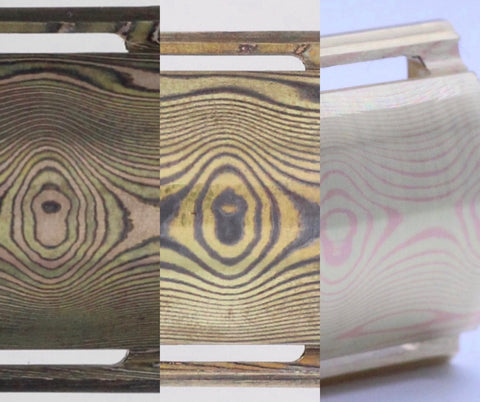

* Same razor but different patina(heat patina on the right)

No worries about rubbing off the pattern, the copper and brass material goes through the piece, it's not just on the surface.

To apply a heat patina on the surface, polish the Mokume with a gentle polish, and be careful around the engraving. Clean the surface very well with isopropyl alcohol...use rubber gloves and don't touch the surface. The oil on your hands will create a patina (fingerprint) on the surface. A Q-tip helps with the cleaning(and polishing). Soak in alcohol...clean really well!

We found a heat patina looks cool and highlights the patterns nicely, it creates a high contrast between the copper and brass. It is also pretty durable but will still evolve.

Heat Patina on a Mokume Gane Safety Razor:

To apply the heat patina, preheat an oven to 400F(Bake). Place the parts on a cooking sheet that is lined with aluminum foil. Cook for 8 minutes the top cap and base plate. The handle and stands will need more time (16 minutes).

Pull the pan out after 8 minutes...let cool. It will be hot...don't touch the parts with your bare hands...I use metal tweezers to take off the pan. Don't scratch the Mokume with the tweezers or drop the pieces!

If you don't like the finish....repolish and try again!

We continue to experiment with the different patinas but have found a polished or brushed surface with a heat patina provides the best starting place for the razor's journey. The patina will evolve, we don’t recommend coating the surface but some jewelers do to maintain the patina they applied. The coating won’t last in a wet environment and we want the razor to show its age and evolve over time. You will find that the material naturally polishes itself where you hold the handle, the cap, and the safety bar will also polish naturally on the edges...

Contours and topography can be introduced to the surface by etching Mokume Gane in acid. The acid will react with the either the brass or copper first, dissolving select material quicker than the other metals creating peaks and valleys in the metal surface. The pattern can then be further enhanced with a layer of patina on the surface, adding more colors to the finish. This is not reversible as it removes material.

The beauty of any patina you apply on Mokume Gane is that it will evolve. Especially in a safety razor, your local water supply will have a big impact on how the colors will mature.

What I like about this material, is you can polish the piece numerous times and apply a different patina...the only thing you cannot reverse is an etched surface as this will actually remove a substantial amount of material...

Light and color are what bring this material to life, the blues, yellows, greens, and blacks can evolve depending on the conditions. The polished appearance of this material is bright and provides a subtle contrasting look.

Shaving with a Mokume Gane Safety Razor

The material is heavier than stainless, and the unique feel of Mokume on the skin is similar to that of copper. The slickness of the surface is lower than that of DLC or polished Titanium/Stainless. With the addition of brass, Mokume is harder than pure copper but still softer than stainless steel, titanium, or stainless Damascus so care should be given. A patina surface will protect the metal from corrosion and a polished surface will naturally protect but it will develop its own patina if not polished, depending on your unique water supply and air conditions.

We periodically make pieces using this material but sadly it is not a readily available material... it's fun to see photos from current customers who have these pieces and see how they look today.

If you are interested in one reach out as we plan to finish up some of these: Contact us